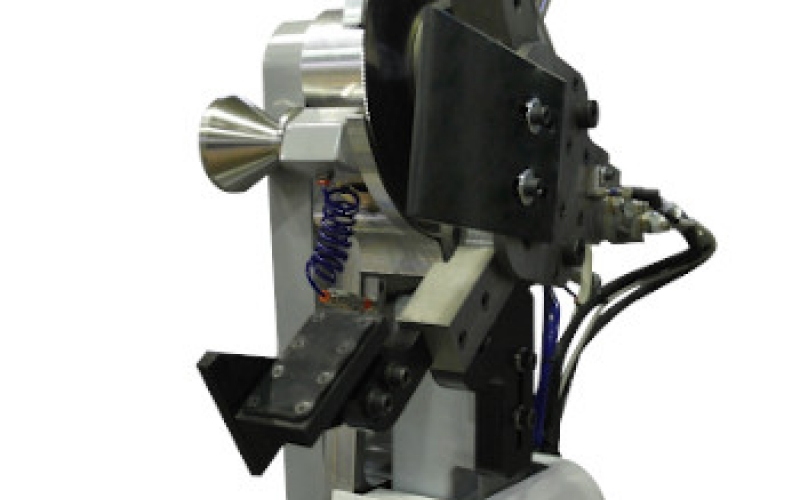

TUBE BENDING MACHINE LEVITATE 935

THE UNIQUE TUBE BENDER FROM COIL WITH MANDREL

A tube bending machine unique in the world

Choose how to cut

Fast and always the same

the tube is always securely held granting maximum accuracy between the bending planes. The clamp avoids deformations and slippings of the tube due to the feeding of the tube by means of rollers. No more marks on the surface of the tubes due to encoders

There is no need for zeroing with zero sensors or limit switches. The machine is always ready from the moment it is switched on

Maximum accuracy and repeatability in positioning

Bend as you want

Quickly change production

You can also end-form

The factory of tomorrow

Respect the environment

Good first take!

Product features

- Maximum workable diameter with mandrel: 35 mm.

- Minimum workable diameter without mandrel: 9.52 mm

- Possibility to bend with or without mandrel

- Right/Left tube bending in process

- Multi-radii bending in process

- Traditional orbital cut (optional)

- Saw blade cut system placed after the bending head

- Electric axes and zero backslash gearboxes allow a constant repeteability over time

- Programmable mandrel extraction in advance

- Not motorized vertical and horizontal straightening rollers

- Not motorized vertical and horizontal calibration rollers

- Quick change systems for the tools

- Possibility to integrate robots and other Simat's machines to have more versative and complete automations

- SimUI HMI, quick and intuitive

- GBS3D graphic simulator

- Sectors: HVAC, automotive, aerospace, furniture